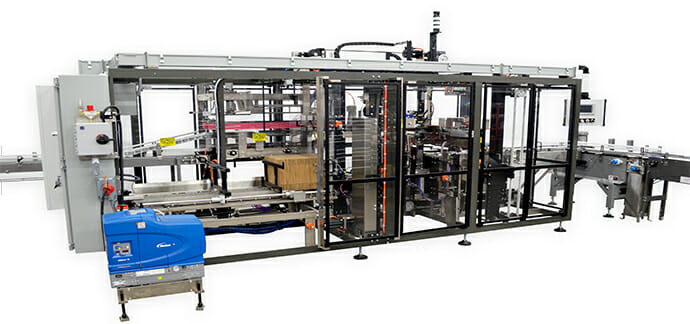

Bottom Load Case Packer Machine

The Bottom Load Case Packer while maintaining a vertical orientation of the RSC case, loads products from the bottom. This design ensures that your products are always fully supported, minimizing any damage or loss of product during the packing process.

If you’re looking for a versatile and efficient case packing solution, Massman Automation’s Bottom Load Case Packers offer a range of advantages:

- Our Bottom Load Case Packers provide gentle handling of your products, ensuring that they remain fully supported and minimizing the risk of damage or loss during the packing process.

- With our bottom load design, you can load flexible or complex products that may not be suitable for other packing methods.

- Our machines are capable of case forming, loading, and sealing all in a single process, streamlining your packing operation – saving valuable time and labor costs.

- This machine’s compact footprint is designed to maximize your floor space while still providing the packing capacity you need.

- Offers a choice of tape or glue closure options, giving you the flexibility to choose the best option for your specific products and application

Request A Quote On A Bottom Load Case Packer