Massman's Talon Equipment for Microwave Popcorn Packaging

Massman's Talon Equipment for Microwave Popcorn Packaging

Massman’s Talon eq uipment offers unparalleled versatility, efficiency, and reliability. Thanks to a two-head system, these popcorn packaging machines can produce up to 300 bags per minute. Automate the process of opening, filling, and sealing popcorn bags using components from an industry leader.

uipment offers unparalleled versatility, efficiency, and reliability. Thanks to a two-head system, these popcorn packaging machines can produce up to 300 bags per minute. Automate the process of opening, filling, and sealing popcorn bags using components from an industry leader.

Microwave popcorn packaging machinery from Talon has a touch-screen interface for easier operation and improved productivity. Combine this equipment with Massman’s palletizing machines to streamline every level of assembly. This machinery will arrange popcorn bags in your preferred pattern flawlessly each time. From individual packaging to case picking and packing, our end-of-line solutions have got you covered.

Microwave popcorn packaging machinery from Talon has a touch-screen interface for easier operation and improved productivity. Combine this equipment with Massman’s palletizing machines to streamline every level of assembly. This machinery will arrange popcorn bags in your preferred pattern flawlessly each time. From individual packaging to case picking and packing, our end-of-line solutions have got you covered.

Read: MASSMAN Automation Designs aquires Talon Manufacturing, Inc.

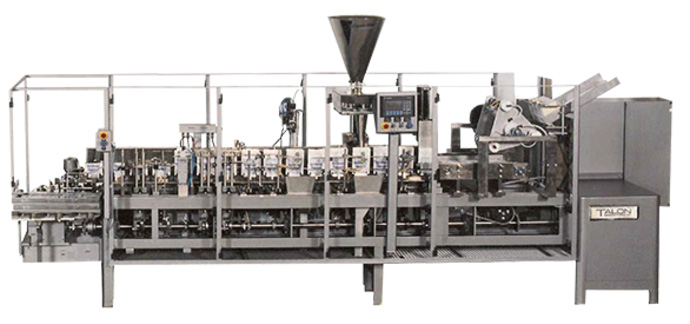

Talon Microwave Popcorn Packaging Machine 90 BPM – 1 – Up

The Massman Talon microwave popcorn packaging machine utilizes a cam and lever mechanical design that provides for a low maintenance and trouble-free operation. An in-line bag magazine feeds a rotary bag placer into clipped flight system. The bags are opened with vacuum, indexed to a volumetric cup filler for corn filling, then indexed to a precision metering pump for liquid filling. The top of the bags are sealed in the seal station, indexed again and folded, then released to the pick off discharge.

Talon Microwave Popcorn 150 BPM – 2-Up Packaging Machine

The Massman Talon microwave popcorn packaging machine utilizes a cam and lever mechanical design which provides for a low maintenance and trouble-free operation. An in-line bag magazine feeds a rotary bag placer into a clipped flight system, the bag is opened with vacuum, indexed to a volumetric cup filler for corn filling then indexed to a precision metering pump for liquid filling. The tops of the bags are then sealed in the seal station, indexed and folded, and finally released to the pick off discharge. Bags are filled a the rate of 150 bags per minute.

GET A QUOTE FOR A TALON MICROWAVE POPCORN 150 BPM PACKAGING MACHINE

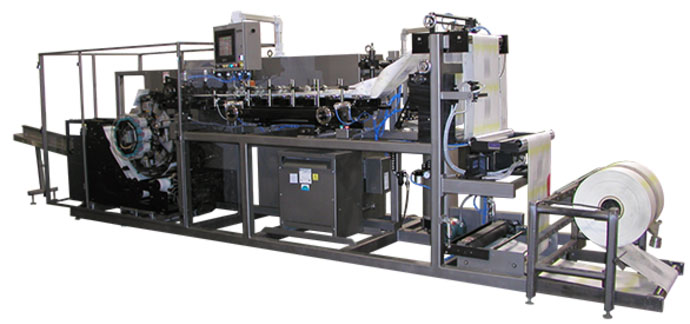

Talon Supra Microwave Popcorn Bag Maker

The Talon Supra Microwave Popcorn Bag Maker utilizes several standard features, including the motorized nip roller to isolate the web tension from the unwind, the web steering system provides control of the web, a side seam glue applicator, and web forming with digital position indicators for accurate and quick set-up. The Supra also includes solid state electronics for drum heaters, an eight-station seal drum, a multi-lingual touch screen operator interface for ease of use, the latest in electronic componentry, a very reliable and low maintenance Servo controlled main nip roller with rotary knife, a shingling conveyor, and a bad bag discharge.

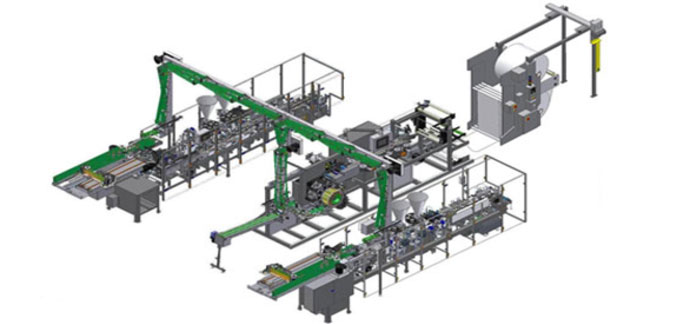

300 BPM Talon Microwave Popcorn Integration Packaging System

The Massman Talon microwave popcorn packaging Integrated System begins with the KTI Dual Unwind Stand, which holds large 42 inch diameter rolls of web material. This web material is then fed into the Supra Bag Maker providing for a continuous operation with the Auto Splice feature. The Supra Bag Maker folds and glues the web material to form the bag. These bags are then conveyed automatically, alternating between two 150 BPM Microwave Popcorn Packaging Machines where the bags are filled and sealed for a combined rate of 300 BPM.

How Microwave Popcorn Packaging Machines Works

Microwave popcorn packaging requires extra care due to the product’s fragility, light weight, and volume requirements. As with all food packing, quality, safety, and efficiency are essential. Our Talon machines’ features provide seamless assembly and consistent results:

- Rotary vacuum bag placer: A rotary vacuum bag placer offers high-speed performance, continuous motion, and multiple configurations. It ensures your popcorn bags are in the correct spot for the vacuum to open them.

- Volumetric cup fillers: Popcorn kernels enter the popcorn bag through volumetric cup fillers. These components preserve the popcorn’s integrity and reliably fill each bag with the proper amount.

- Precision metering pumps: Metering pumps evenly distribute flavorings and cooking oil. Their accuracy minimizes spills and other incidents that impact your productivity.

- Heated top seal stations: After being filled, bags are indexed to the seal station. Heated top seal stations give your packaging a uniform, airtight finish that prevents leakage.

- Guillotine-style bag folder: The bag folder’s guillotine blades offer clean cuts, ensuring neat folds and professional outcomes every time. Once the bag is folded, it goes to the pick-off discharge.

A popcorn packing machine can be semi-automatic or automatic. Both variants have the same filling process, but the semi-automatic version has a separate sealing station.

How Packaging Machines Serve Popcorn Packaging Needs

In a competitive business environment, you want an innovative, reliable packaging solution. Get the most value out of your investment with our numerous packing options. Massman offers microwave popcorn packaging equipment to meet your specific needs, including:

- 150 BPM – 2-Up Packaging Machine: Our 150 BPM Packaging Machine has a cam-and-lever design, providing you with minimal maintenance requirements, smoother operations, and exceptional packing performance.

- Talon Supra Microwave Popcorn Bag Maker: The Supra Microwave Popcorn Bag Maker comes with state-of-the-art features like a servo-motorized nip roller, digital position indicators, and an eight-station seal drum. Its low-maintenance design offers the accuracy and efficiency you need for creating pre-made popcorn bags.

- 90 BPM – 1-Up Packaging Machine: With the 90 BPM Packaging Machine, you can process bags at a rate that matches your requirements and preferences. A lower BPM option improves your productivity while maximizing your budget.

- 300 BPM Integration Packaging System: The 300 BPM Integration Packaging System seamlessly links automated bag making to two 150 BPM Packaging Machines for continuous, high-speed production.

The Benefits of Packaging With Massman

Companies of any size can benefit from packaging with Massman. Enjoy our unique advantages, which include:

- Ease of change-over: We can easily retrofit our Talon equipment to suit any production size and speed. If your business’s needs change, we’ll help you make the transition.

- Exceptional reliability and efficiency: Massman’s popcorn packaging machinery is durable, consistent, and efficient. We fuse the precision of traditional packaging with product automation, boosting your total output and bottom line.

- Fantastic cost value: Talon equipment pays for itself by lowering labor costs, production time, and ergonomic issues.

- Comprehensive customer service: From preventative maintenance programs to 24-hour live personal coverage, our technicians have the expertise and dedication to help you succeed.

Choose Massman to Make Packaging Popcorn Easier

For over four decades, Massman has supplied businesses like yours with cost-efficient, rugged, and dependable packaging solutions. We dedicate ourselves to helping you meet market demand and get the job done right every time. Whatever your application or company needs are, you’ll have a packing machine and a team you can count on.

Interested in working with Massman Talon for your packaging automation? Give us a call at 320-554-3611 or request a consultation today to learn more about how we can transform your operations.