Custom Automated Packaging Machines

Custom Automated Packaging Machines

Massman Automation has automated the packaging of storm doors, vinyl siding, fluorescent lamps, washers and dryers, and other large challenging packaging requests. We have been providing custom automated solutions for more than 40 years to a wide variety of industries, using robotics, servo motors, pneumatics, and unique line shaft cam configurations. Let us help you with your unique and challenging packaging application.

Massman can also integrate several different types of robots of various sizes to automate the product handling for a wide variety of industries. Massman uses robots to accomplish complicated articulated motion, high-speed flex-picking applications and continous heavy lifting applications, such as palletizing. We can also add a vision system where required.

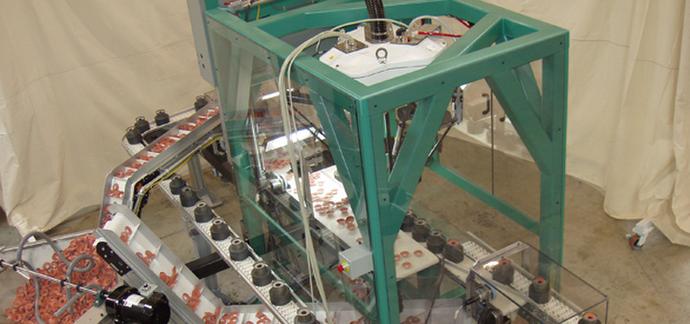

High Speed Robotic Vision Sorting and Assembly Systems With Vacuum EOAT

Massman Engineering is providing the filter industry with automation solutions.

An ABB Flex Picker robot with a custom vacuum end-of-arm tool (EOAT) provides high-speed picking of bulk part fed components with extremely accurate part placement and quick changeover capabilities. The system can also employ a vision system as needed.

High-Speed Robotic Vision Sorting & Assembly Systems

Massman Engineering is providing the filter industry with automation solutions.

An ABB Flex Picker robot with a custom magnetic gripper end-of-arm tool (EOAT) provides high-speed picking of bulk part-fed components with extremely accurate part placement and quick changeover capabilities. The systems can also employ a vision system as needed.

GET A QUOTE ON A HIGH-SPEED ROBOTIC VISION SORTING & ASSEMBLY SYSTEMS

High-Speed Robotic Vision Sorting and Assembly With a Gripper EOAT

Massman Engineering is providing the filter industry with automation solutions.

An ABB Flex Picker robot with a custom gripper end-of-arm tool (EOAT) provides high-speed picking of bulk part fed components with extremely accurate part placement and quick changeover capabilities. The systems can also employ a vision system as needed.

GET A QUOTE ON HIGH SPEED ROBOTIC VISION SORTING & ASSEMBLY WITH A GRIPPER

Soffit/Vinyl Siding Case Packer

The soffit/vinyl siding case packer erects a long wraparound style case blank, then collates the product and push-loads the product through the end of the case prior to sealing the case.

Massman Automation utilizes its large corrugate blank handling expertise and unique product handling capabilities to provide a wraparound case packer for the building trades industry.

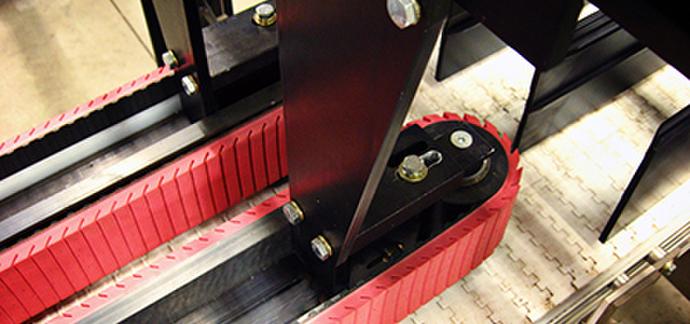

Lane Dividers

Massman Automation offers a variety of different lanes dividers to handle several product profiles and speeds.

Massman Automation incorporates its proven case packer infeed technology and offers standalone plaque style lane dividers, flood feed infeed dividers, and swinger lane dividers.

Fluorescent Lamp Case Packer Machine

The fluorescent lamp case packer is capable of handling T5, T8, and T12 lamps in lengths from 2’ – 8’ in a variety of different pack pattern configurations with pulp tray dividers.

Massman Automation utilizes its large corrugate blank handling expertise and unique product handling capabilities to provide a wraparound case packer for the fluorescent lamp industry.

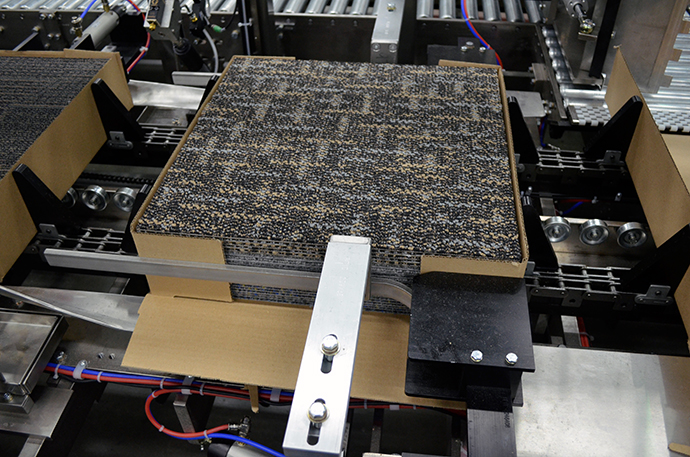

Tray/Lidder for Flooring Automation

Massman has over 40 years of experience packaging products with an extensive industry range. Whether you need your flooring packed in cases, trays, shrink wrapped or bundled we have a solution for you.

Custom Machines

Massman Automation Designs can help you with any packaging need, including unique and complicated applications. We offer custom machines and robotic solutions for specialized industries and products incompatible with a standard system.

Our engineers will use line shaft cam configurations, pneumatics, servo motors, and robots to manufacture custom machines for you. This method includes integrating several types of various-sized robots for automated product handling. We use robots for:

- High-speed flex picking.

- Continuous heavy lifting, like palletizing.

- Complicated articulated motion.

If your application needs a vision system, we can add it to your solution.

Massman has completed custom automated solutions for challenging packaging requests such as:

- Vinyl siding.

- Washers and dryers.

- Fluorescent lamps.

- Storm doors.

Custom Machine Services Offered

The custom automated solutions at Massman Automation Designs provide packaging robotic solutions tailored to your specific requirements. When you choose us for custom machines, you’ll have the advantage of our complete design and manufacturing capabilities, including:

- Machine design: Our team will design your automated packaging machine. We’ll create a conceptual rendering, documentation, and other specifications.

- Engineering: Our design and manufacturing process utilize top-of-the-line software and technology for quality assurance.

- Development: Massman will identify the tools and technology needed to create your custom machine.

- Control systems: Our robotic solutions can include nearly any standard or engineered control system you specify, such as wireless remote options.

- Motion control: Massman Automation Designs will ensure your custom machine has the best components and architecture. Once your machine is installed, we can offer further support like field service repairs or formal equipment training.

The Advantages of Custom Machinery

Automated packaging solutions can improve your productivity and output. When you add robotic solutions tailored to your application in your production line, you’ll gain certain benefits like:

- Reliable and efficient: Using a custom machine to package products leads to more reliable results and efficient processes compared to hand filling. Every product will be packed the same way.

- Low shipping costs: Packaging too small or large for the product can damage the item, waste packing materials and increase shipping costs. Custom machinery can create packaging at the right size for the product, keeping the item safe and cost efficient during transport.

- Codevelopment: Custom automated solutions by Massman encourage collaboration between design and manufacturing. This process reduces issues and production delays, so you can get your custom machine more quickly.

Interested in Working With Massman?

Massman Automation Designs has more than 40 years of experience in designing and manufacturing custom automated solutions. Our engineering expertise allows us to offer systems for many products and applications while customizing the machine to exact specifications. Whether you’re a small company looking to expand your operations or a large corporation searching for a reliable packaging solution, Massman can design a packaging machine tailored to your specifications for a fair price.

Need a custom automation machine? Massman can design and manufacture a packaging solution that will package your products quickly and cost-effectively for enhanced efficiency. Call us at 320.554.3611 or request a consultation today!