Tying and Tin Tie Equipment

Tying and Tin Tie Equipment

The tying equipment at Massman Automation Designs includes machinery that seals pouches and bags using a tying method. Our bag closer machines use tin ties, adhesive tape, and automated hose coilers to create an effective seal. We also can customize equipment to meet your exact needs.

4100 Series Tin Tie Applicator/Double Fold Bag Closer

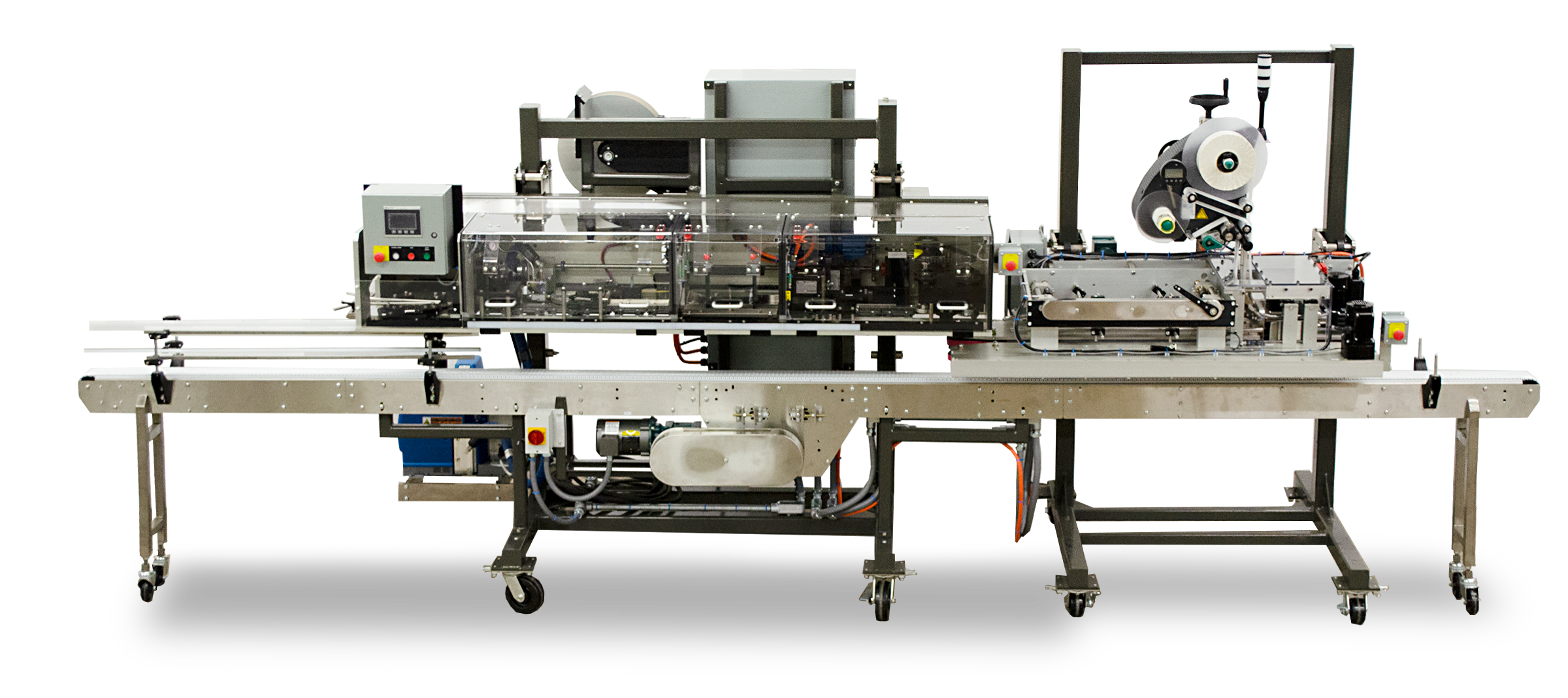

Massman Automated Bag Closer – Glued Double Fold with Tin Tie

The 4100 Series Tin Tie Applicator/Double Fold Bag Closer is a completely automated bag finishing system. The 4100 Series trims the bag tops, double creases them for crisp consistent folds, and applies tin ties with hot melt adhesive. It then double folds the bag tops, glues the folds with hot melt adhesive and bends the tie tabs around the folds. Optional equipment is available to re-gusset the bag tops to align their corner edges, space the bags for consistency through the machine, and/or plow down and tape down the bag tops for tamper evidence.

GET A QUOTE ON A 4100 SERIES TIN TIE APPLICATOR & BAG CLOSER

Tin Tie Applicator with Single Fold Bag Finisher

Massman Tin Tie Applicator with Single Fold Bag Finisher

The 4500 Series finishes filled and sealed bags by adding the tin tie reclosures and single folding the bag tops. The 4500 Series applies the tin ties to the bags with hot melt adhesive, single folds the bag tops and automatically bends the tie tabs around to hold the folded flaps. The 4500 Series can be built to place the tin tie inside OR outside the single fold. This machine can also be integrated with a vertical form fill and seal machine to provide reclosable packages from a completely automated system.

Semi Automatic Tin Tie Applicator

The Semi Automatic Tin Tie Applicator is available in the 2200 Series (pictured) and the 2500 Series. The LX2200 and RX2200 tin tie machines place .315″ wide, double wire tin tie, on bag faces of filled bags. Filled bags would normally be pre-sealed. The tin tie is applied using a hot melt adhesive. The 2500 Tin Tie Machine places .315″ wide, double wire tin tie on bag faces of filled bags. Filled bags would normally be pre-sealed, and as with the 2200 Series, the tin tie is applied using a hot melt adhesive. The tie ends extending past the edge of the bag are then automatically bent around the bag neck for a finished look.

Automated Tying Equipment

An automated bag closer offers a mechanical method to simply and easily tie or bundle products with twine. The process is straightforward:

- The products that need to be bundled go into the machine.

- The rotating arm goes around these items twice.

- On the second rotation, the twine is mechanically knotted.

Tying machines are more efficient than manual labor. They can tie up to 20 packs per minute. Bag closer machines are useful for any application that needs string to be tied around products, such as mail houses, laundries, and printers.

Tin tie applicators attach a metal strip to the top of a bag, and its ends bend over the fold to seal the bag. These machines are sequenced for every step of the application process:

- The bag enters the machine.

- A hot-melt adhesive is applied to the top of the bag.

- A tin tie, already cut to the desired length, is attached to the bag.

- The top of the bag is folded once or twice.

- The ends of the tin tie are bent around the folded part of the bag.

Tin tie applicator machines are common for coffee and baked goods.

Types of Tying Machines

Massman has three main types of tying machines — tin tie applicators, automated bag closers, and semi-automatic tin tie applicators. These bag closure machines work in a few ways:

- Filled pouch with tin tie closure application: The machine uses a hot-melt adhesive to attach the tin tie to the bag, folds the bag top once, and bends the tin ties on the inside or outside of the single fold to keep the flaps down.

- Folded pouch with adhesive tape application: A label applicator applies clear tape to the back of the bag where it is folded down. The tape proves tamper resistance and a means for the customer to seal the bag.

- Automated hose coiler with tie application: The machine winds and ties hose, tubing, or any material that needs to be coiled. It automatically winds, ties, and ejects the coil.

The Advantages of Automated Tying

Automated bag closer machines have several benefits for your business:

- Easy access for cleaning: Our tying equipment is designed so all areas of the machine are accessible for cleaning.

- Simple maintenance: The accessibility in the machine also makes repairs and maintenance much more manageable.

- Quiet operation: The motors in the automated bag closer machines run quietly to prevent noise pollution and promote a safe working environment.

- Reliability: The simplicity and motion control features encourage reliable operation and a durable machine.

- Safety for employees: The machines have user-friendly controls for setup and safety features like foreign object detection to prevent injuries.

Interested in Working With Massman?

Massman Automation Designs has over 40 years of experience providing our customers with tying equipment made for their unique applications. We have a reputation for innovation, so you’ll receive the highest-quality technology advancements when you partner with us.

If you’re ready to work with Massman on your bag closure machine project, reach out today. Request a consultation or call 320-554-3611.