Palletizing Equipment and Systems

Palletizing Equipment and Systems

Massman can design, build, and install a complete end-of-line system tailored to your specific application. We have been providing complete packaging solutions to a wide variety of industries for more than 40 years.

Massman Automation offers a small footprint, low-cost gantry palletizing solution, a high-entry palletizing solution, and robotic palletizing solutions capable of handling multiple conveyor lines.

Automation Robotic Palletizing

The robotic palletizer is capable of picking multiple cases with vacuum or mechanical end-of-arm tooling (EOAT) and building the desired pallet pattern.

Massman Automation integrates ABB, Fanuc, or Motoman robots into the robotic palletizing cell. These systems handle multiple packaging lines with multiple SKUs featuring ALBA pallet dispensers and pallet conveyors which are compatible with many custom-designed case and pallet handling systems.

High Entry Palletizer Machine

The Massman Automation high entry palletizer is a great solution for palletizing 40-pound cheese blocks for the dairy industry.

The high entry palletizer accepts a case, rotates the case if necessary for label viewing, and creates rows of cases to achieve the desired tier pattern (to provide a cooling chimney where necessary), places a layer sheet as required, then lowers the pallet for the next tier, and repeats this process until the pallet is completed and discharges via a powered pallet conveyor.

Incorporating both conventional and robotic palletizing technologies, this palletizer system ensures efficient and precise handling of cheese blocks while maintaining product integrity. With its advanced arm tooling and sophisticated row forming capabilities, the system can adapt to various packaging types and sizes. It offers a versatile solution for dairy processing facilities. From sorting and transferring to stacking and forming, enhancing overall productivity and efficiency.

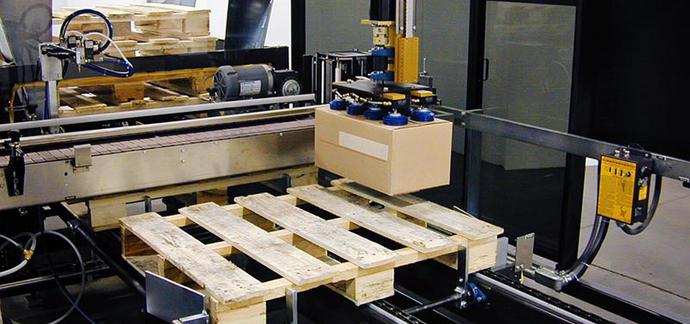

Gantry Palletizer Machine

The Massman gantry palletizer is capable of picking multiple cases with vacuum or mechanical end-of-arm tooling (EOAT) and building the desired pallet pattern including the placement of base and layer sheets.

Massman Automation integrates servos for the X, Y, Z axes that place the layer pattern in the selected orientation to build the desired pallet pattern. the gantry palletizer features ALBA pallet dispensers and pallet conveyors with many custom designed case and pallet handling options. This small footprint palletizer is ideal for placement directly downstream of a Massman Automation case packer.

What Is Palletizing?

Palletizing is the act of placing products, goods, or materials on a pallet for storage or shipment in a logistical supply chain. The product is stacked by weight and volume in a pattern that maximizes the number of items on the pallet and ensures that the load is stable and the goods will not shift or topple into one another. Though palletizing was initially accomplished manually, the growing popularity of palletizing equipment has resulted in a preference for automation.

Case palletizing equipment automatically sorts, transfers, and stacks cases of products or goods onto pallets, typically at the end of a manufacturing line. With these palletizing systems, users can facilitate high-volume shipping quickly, precisely, and conveniently while transporting larger loads.

Automated palletizing solutions were developed to minimize worker injury and speed up production processes, resulting in the row-formed machine, which placed pallet products in neat rows. Today, modern palletizing machines feature advanced technologies like robotics and computers, and they can manage items that are difficult to palletize by hand, such as bottles.

Palletizing Equipment and Systems Through Massman

When you come to Massman for reliable palletizing systems, you’ll have access to all of the following equipment options:

- Robotic palletizing: This palletizing solution can grab multiple cases at once using mechanical or vacuum end-of-arm tooling (EOAT) to build the intended pallet pattern. It can handle numerous packaging lines with various stock keeping units (SKUs).

- High-entry palletizer: Our high-energy palletizers accept a case, rotate it for optimal label viewing, and generate rows to achieve the desired tier pattern. They then insert a sheet layer and lower the pallet for the next tier, repeating the process until the pallet is complete.

- Gantry palletizer: Like robotic palletizing systems, the gantry palletizer can pick up numerous cases with vacuum or mechanical EOAT. They feature X, Y, and Z servo axes that place the layer pattern in the proper orientation for the desired pallet arrangement.

The Advantages of Palletizing Automation

Palletization has had a direct impact on material handling improvement, making the process faster and more efficient than ever. When you automate your processes using case palletizing equipment in your facility, you’ll experience several benefits:

- Fewer damages: Because palletizing robots can perform more accurately and precisely than manual workers, they minimize the risk of product damage due to drops. Automated equipment won’t rush, get distracted, or misinterpret SKUs, leading to fewer mistakes.

- On-time production: Automated palletizing solutions are significantly faster than people and have a much more predictable output. You know exactly how many cycles the machine can run per minute, and you won’t have to account for breaks like you would with human beings.

- Improved safety: Workplace injuries typically result from repetitive motion, heavy lifting, and manual stacking and unstacking. Palletizing systems eliminate the risk of damage by replacing workers in hazardous situations.

- Fast turnaround: Palletizing equipment streamlines the loading and unloading process, resulting in greater transport efficiency and faster turnarounds.

Interested in Working With Massman?

You can secure top-of-the-line palletizing equipment that sets the standard for innovation and user-friendly operation at Massman. We’ve spent over four decades creating standard and custom palletizing solutions that meet our customers’ needs. Our team has the knowledge, experience, and technologies needed to modify and adapt our designs to your individualized application needs.

Get started with our automatic palletizing machines by requesting a consultation or giving us a call at 320-554-3611 today!