18 November 2024 //

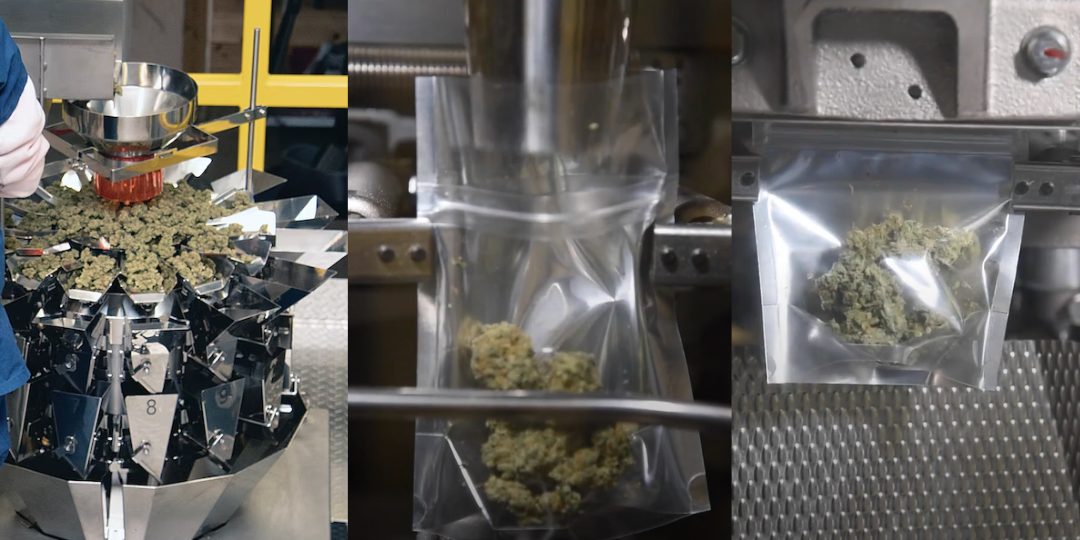

Cannabis Packaging: The GP-M3000 Pouch Filling Machine In Action

In the rapidly evolving cannabis industry, efficiency and innovation in packaging are crucial. Massman Automation, a leader in automation solutions is supplying and servicing the GP-M3000 Automated Bag Filling & Sealing Packaging Machine – A game changer for cannabis businesses!

In a recent project with Artemis, a co-packing facility in Northern California, co-founder Autumn discussed in an interview how her team is automating their packaging processes to meet co-packaging demands efficiently and to make partnering with small businesses more financially viable. Artemis focuses on postprocessing steps like weighing, sorting, and packaging, allowing cannabis cultivators to concentrate on what they do best—cultivation. As Autumn explains in the video below, “Providing a pathway for farmers to be able to package their product with the same machinery that corporate interests are using is super important,” emphasizing their mission to bring scalable, high-quality automation capabilities to the broader market.

As part of their packaging line, Artemis has installed a GP-M3000 pouch filling machine. Artemis’s VP of Operations, Taylor Coomer, described the packaging process that takes place after the cannabis flower is dried, cured, and stored. Paired with other end-of-line weighing and packaging equipment, the GP-M3000 efficiently handles the bagging process, streamlining production for cultivators. Taylor noted that the machine boasts a capacity of up to 65 pouches per minute, though current production levels haven’t yet fully utilized this capacity. With two operators managing the end-of-line packaging, they are able to meet the demands of their co-packing plant and are highly satisfied with the machine performance and capabilities.

Watch the full video produced by CannaCribs featuring co-packer Artemis, Massman’s GP-M3000 pouch filler and the cannabis packaging process:

Learn More About The GP-M3000 Pouch Filling Machine

Massman’s Exclusive Distribution of the GP-M3000 In North America

Massman Automation takes pride in being the exclusive North American Authorized Distributor for General Packer, the manufacturer of the GP-M3000. This partnership ensures not only the availability of this advanced equipment but also reliable support and service for North American clients.

In an industry where precision, efficiency, and compliance are key, the GP-M3000 by Massman Automation offers an ideal solution. Capable of handling speeds up to 65 packages per minute and accommodating pouch sizes up to 4.4 pounds, this machine streamlines the packaging process with remarkable efficiency. It ensures consistency and quality in every package, while its advanced sealing technology maintains product integrity. For cannabis businesses aiming to enhance their operational capacity, the GP-M3000 not only meets but exceeds expectations. This solution offers small businesses the same opportunities for product quality and efficiency that large businesses are utilizing, helping them keep up with production demands in a competitive market.

Advanced Flexibility and Efficiency

The GP-M3000 stands out for its versatility. It easily manages various pouch configurations, including stand-up pouches, side-gusseted, flat-bottom, and 3-side seal pouches. This flexibility allows cannabis businesses to adapt to different product types and packaging designs, enhancing their market appeal.

Sealing with Precision

The machine’s capability extends to sealing pouches with reclosable features. Whether it’s Press-to-Close Zippers, eSliders, or Velcro, the GP-M3000 ensures airtight and secure sealing, maintaining product freshness and integrity – a vital aspect for preserving the quality of cannabis products.

Enhanced Precision with Weighing and Infeed Components

The GP-M3000’s design allows for the integration of additional components to further streamline the packaging process. Pouches are efficiently fed into the machine via a conveyor system, which ensures precise alignment and placement into the pouch clamps. This meticulous process guarantees consistent pouch handling every time. The machine’s rotary system then proceeds through a series of steps including opening non-child proof zippers, printing date and lot codes, and filling the pouches. A key feature is the optional integration of a weighing system, ensuring accurate product quantities in each pouch. Vibrators are used to settle the contents completely, and optional gas flushing can be performed for product preservation. The machine’s advanced heat-sealing unit supports a quick, automated change in pouch size, reducing downtime significantly. Constructed from heavy-duty stainless steel with a hygienic design, the GP-M3000 promises both durability and easy cleanability, making it an ideal choice for cannabis packaging needs.

Ease of Use and Dedicated Support by Massman

Massman Automation distinguishes itself with exceptional customer support for the GP-M3000. Offering 24-hour service, comprehensive training, preventative maintenance programs, readily available spare parts, and dedicated technicians. This comprehensive support ensures ease of use and reliable performance, highlighting Massman’s commitment to customers’ success.

Massman Automation’s GP-M3000 emerges as a cornerstone in cannabis packaging, offering unparalleled precision, flexibility, and efficiency. This advanced machine stands as a testament to Massman’s commitment to driving innovation in the cannabis industry, ensuring quality and consistency in every package.

To Discuss Automating Your Packaging

CONTACT US

Visit Machine Page: GP-M3000

Read more about the GP-M3000: Brochure

Learn about how Harvest Health and Recreation Inc. grew its packaging line to meet the growing market and demand: Case Study For Harvest Health and Recreation Inc.