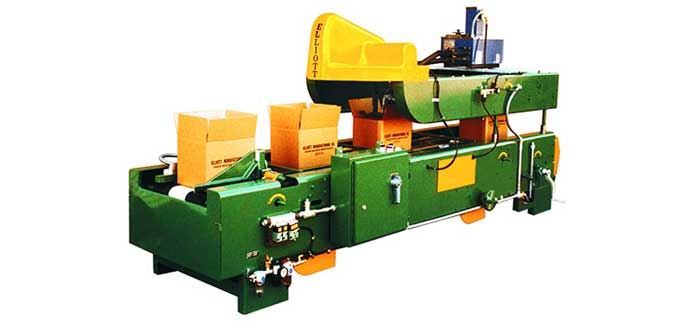

Elliott Model 76-10 Fully Automatic Hot Melt Case Sealer

The Elliott Model 76-10 Fully Automatic Hot Melt Case Sealer is a compact machine for sealing a wide range of case sizes in limited space. It is quickly adjustable for case size changes. The Model 76-10 is built with a single unitized machine frame and has a transfer system that ensures a square case every time.