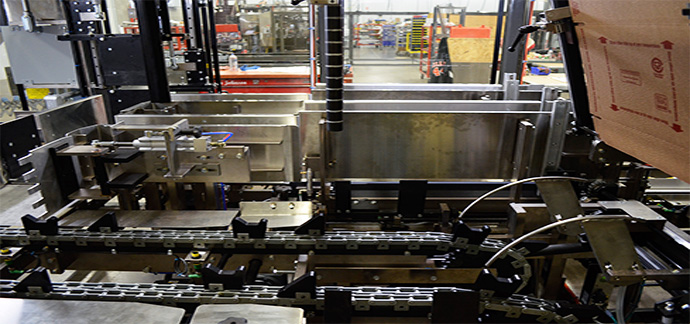

Massman Automation Wrap Around case packers are designed with safety, durability, productivity and efficiency as the top design criteria. In addition, the Wrap Around case packer is capable of handling harness style case blanks, trays with or without display windows, and case blanks with tear-off perforations. The Wrap Around case packer is designed to your specifications. These heavy-duty machines are built to be dependable under multi-shift conditions. With Massman Automation’s in-house technical expertise in the design and programming of this equipment, you can be assured of years of efficient productivity and low-cost ownership.

The wrap around case packer has several advantages over other case packing options. This machine is capable of handling the wrap around case blanks. harness style case blank, and tray blank.

Advantages

- Potential Corrugate Savings

- Multiple Case Style Options

- Outside or Inside Manufacturing Flap

- Increased Case Blank magazine Capacity

- Open Case Loading for Positive Product Handling

- Full Over Lapping Flaps (FOL) Capabilities

| Specifications |

Standard Option |

Additional Options |

| Case Blank Capabilities |

Wrap Around blanks |

Tray style case blanks

Harness style case blanks

Knock down (KD) style case blanks |

| Infeed Options |

|

Lane divider with grouping (ideal for bottles & jugs)

High speed rotary upstacker (ideal for cartons)

Low speed bump upstacker (ideal for cartons)

Flood feed (ideal for cans)

Racetrack infeed (ideal for cartons & sleeved product)

Indexing paddles (ideal for cartons & sleeved product) |

| Product Loading |

Servo driven cross push mechanism |

Mechanical gripper

Vacuum gantry

Overhead loader

Robotic |

| Magazine |

3’ low level power-feed magazine |

6’ power-feed magazine

Low level magazine

Dual blank magazine

Opposing cup case setup |

| Glue System |

NORDSON ProBlue® Series |

Inside manufacturers flap

Inline compression of manufacturers flap |

| Guard Doors |

Aluminum extruded frame with 1/4” clear or dark acrylic panels |

Stainless steel mesh panels |

| Frame |

3”x3”x1/4” wall tubular mild steel frame |

300 series stainless steel

300 series stainless steel with no penetrations |

| Frame Finish |

Powder-coat polyester resin finish |

|

| Electrical |

Allen Bradley Human Machine Interface (HMI)

Allen Bradley Panel View 700 with ethernet capabilities (wago)

Allen Bradley compact logix PLC with ethernet capabilities

Allen Bradley guard door switches (interlock doors)

Bosch indramat servo motors and drives

Allen Bradley 3-color light stack with audible alarm

NEMA 12 electrical enclosure with external power

receptacle and computer port

Interface wireway

Category III safety circuit

480 VAC, 3ø, 60 Hz |

Allen Bradley PV 1000+ ethernet capabilities

Allen Bradley control logix PLC with ethernet capabilities

Allen Bradley Kinetic 6000 servo motors and drives

NEMA 4x electrical enclosures and standards

Integral lay in perimeter wireway

240 VAC, 3ø, 60 Hz |

| Pneumatics |

Busch dry vane vacuum pump

SMC valves and cylinders

Parker fittings |

Venturi vacuum generators

Centralized enclosure |

| Adjustments |

Digital indicator with handwheels |

Power adjustment for movements over 12” |

Wrap Around Blanks

1. The wraparound case blanks are loaded into the case blank magazine to be dispensed into operation.

2. The wraparound blank is pulled from magazine and erected in the set-up station.

3. The erected case is then indexed to the load station where product is loaded into the case.

4. The case then indexes to the gluing station, while manipulating major and minor flaps.

5. The case is squared and compressed to allow the glue to set and then the case is discharged.

Harness Blanks

1. The harness style case blanks are loaded into the case blank magazine to be dispensed into operation.

2. The harness blank is pulled from magazine and erected in the set-up station.

3. The erected case is then indexed to the load station where product is loaded into the case.

4. The case then indexes to the gluing station, while manipulating major and minor flaps.

5. The case is squared and compressed to allow the glue to set and then the case is discharged.

Tray Blanks

1. The tray case blanks are loaded into the case blank magazine to be dispensed into operation.

2. The tray blank is pulled from magazine and erected in the set-up station.

3. The erected case is then indexed to the load station where product is loaded into the tray.

4. The case then indexes to the gluing station, while manipulating major and minor flaps.

5. The case is squared and compressed to allow the glue to set and then the case is discharged.

With Massman Automation’s complete line of case packers and our ability to customize that offering, our customers can be assured of getting the right machine solution for their application.

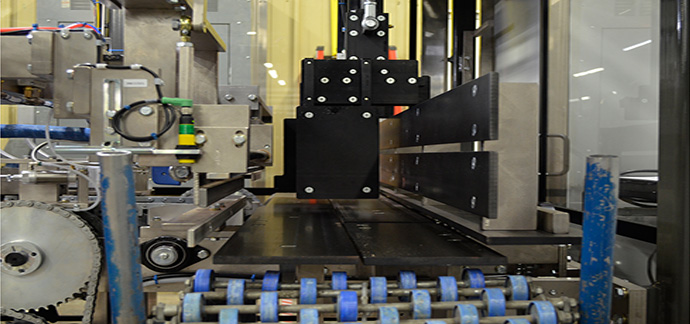

Infeed Options

Selecting the correct infeed option is crucial to the success of any case packing application. Massman Automation has the right infeed solution for your product.

- Low speed bump upstacker

- 90 degree push load

- Race track

- Upstacker with product support

- Flood feed

- Swinger lane divider with grouping

- Indexing paddles

- High speed rotary upstacker with surge/metering belts

Magazine Options

Massman Automation offers different case blank magazines to handle all types and sizes of corrugate and chip board blanks, with many unique design features to ensure proper blank.

- Dual blank style(WA, KD, or Tray)

- Opposing cup set-up

- Vacuum transfer (Bottom load only)

- Low level magazine

- Standard 3′ o 6′ case bank magazine

- 4′ case blank magazine (Bottom load only)

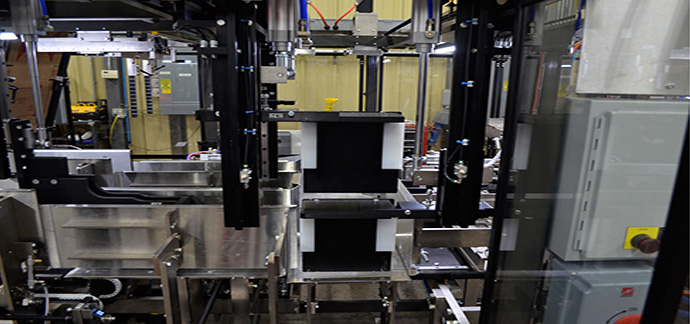

Product Loading Options

With this complete line of Case Packers, Massman Automation has the right product loading option for your product.

- Robotic

- Cross push

- Vacuum Gantry

- Servo driven overhead loader

- Bottom up push

- Mechanical gripper

Electrical Standards

Massman Automation takes a simplistic “user friendly” approach to the machine interface incorporating multiple enhancements to assist the machine operation.

- Air exchange

- HMI 700

- Heavy section power adjust

- Interface wire way

- Lock out – Tag out

- Light stack

- Interlock guard doors

- Allen Bradley – PLC

- Category III safety circuit

- Allen Bradley servos

- Pneumatic safety

Machine Standards

Massman Automation utilizes years of experience to prove its customers with equipment that has a very solid selection of purchase components and engineered designs.

- Heavy duty frame

- Adjust digital indicator

- Nordson hot melt glue system

- Vacuum pump

- 1/4″ Acrylic guard doors

- Stainless steel mesh guard doors (optional)

- Busch vacuum pump

- SMC air cylinders

- Vacuum filter

- Heavy duty lift off

- SMC pneumatics

- Boston gear boxes

- Festo Pneumatics

- Festo Cylinders